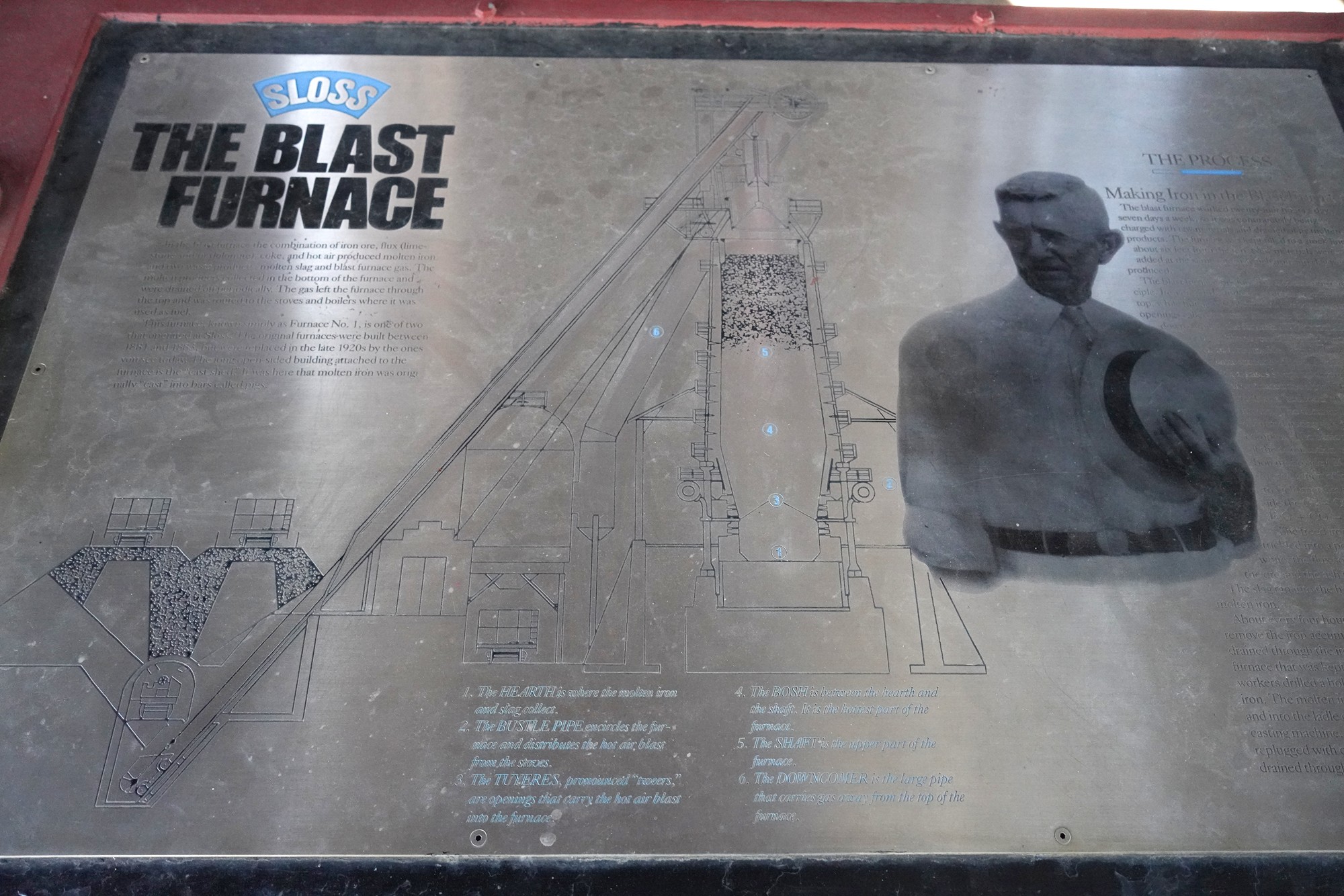

Sloss Furnaces National Historic Landmark, Birmingham, Alabama, USA

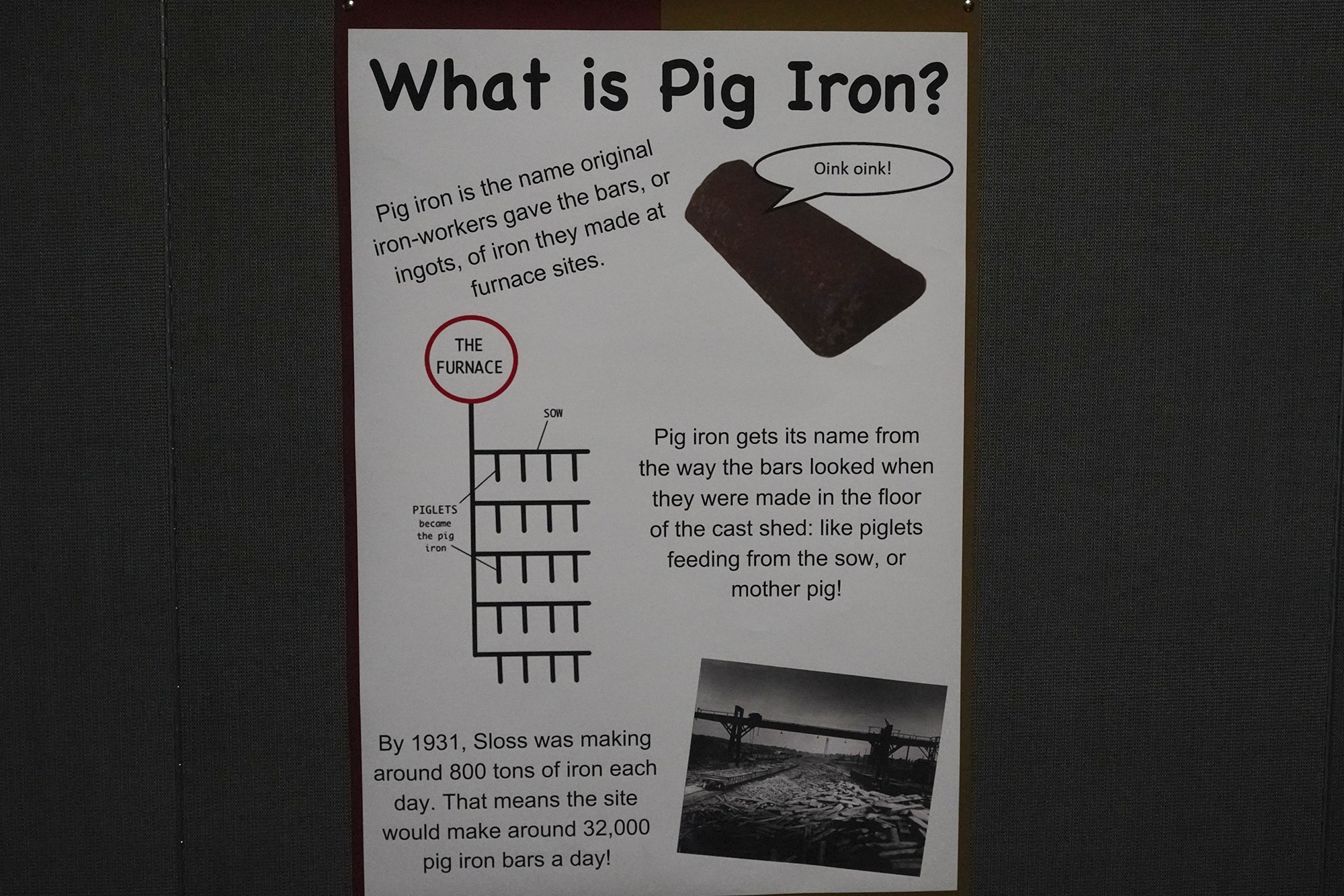

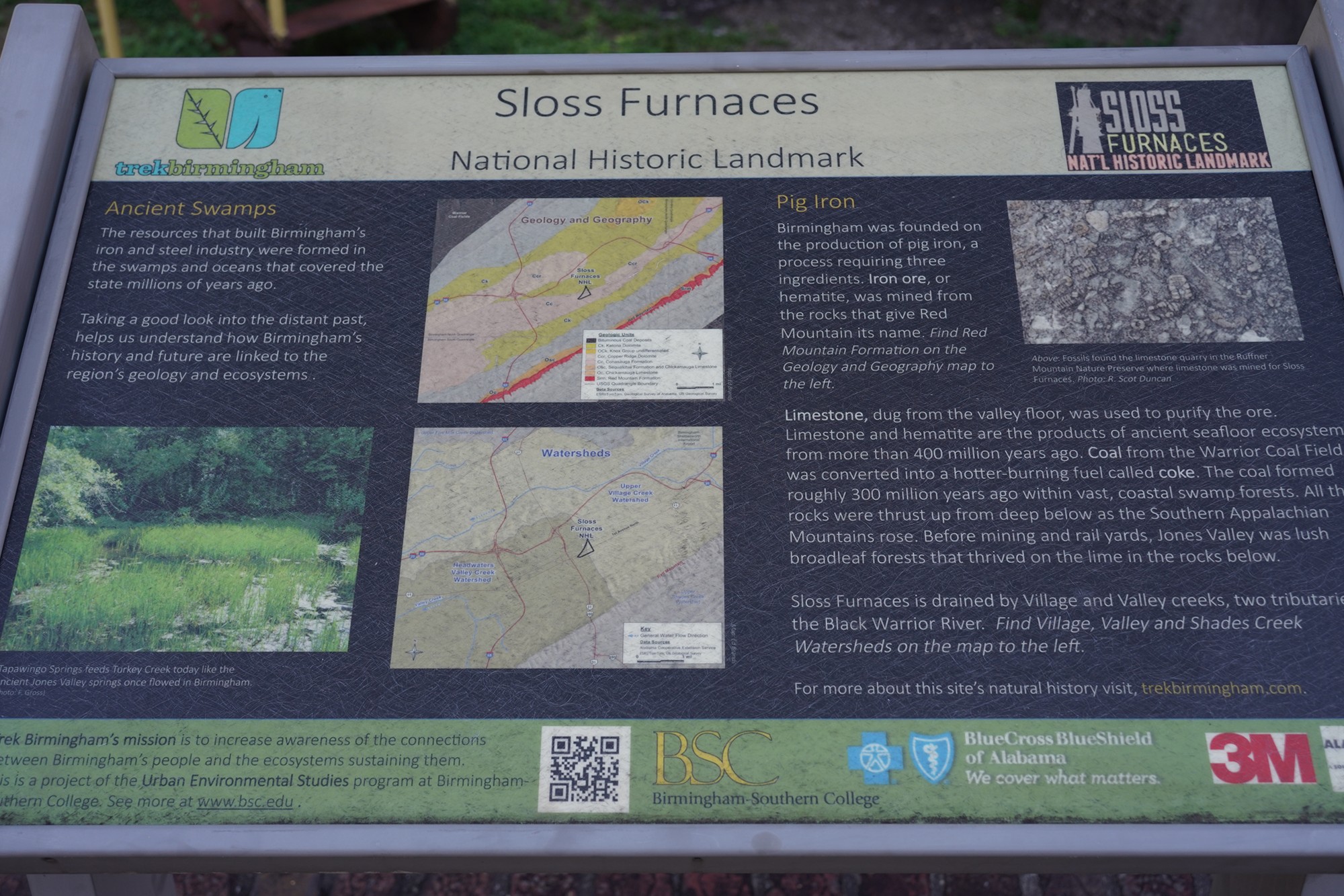

From 1882 to 1971, it operated as a pig iron-producing blast furnace. After closing, it became one of the first industrial sites in the U.S. to be preserved and restored for public use. 509

SLOSS Furnaces National Historic Landmark: 20 32nd St N, Birmingham, Alabama

Date Picture Taken: September 2022

The site currently serves as an interpretive museum of industry and hosts a nationally recognized metal arts program. It also serves as a concert and festival venue. A new visitor center was built 2015 and opened in 2016.

The visitor center

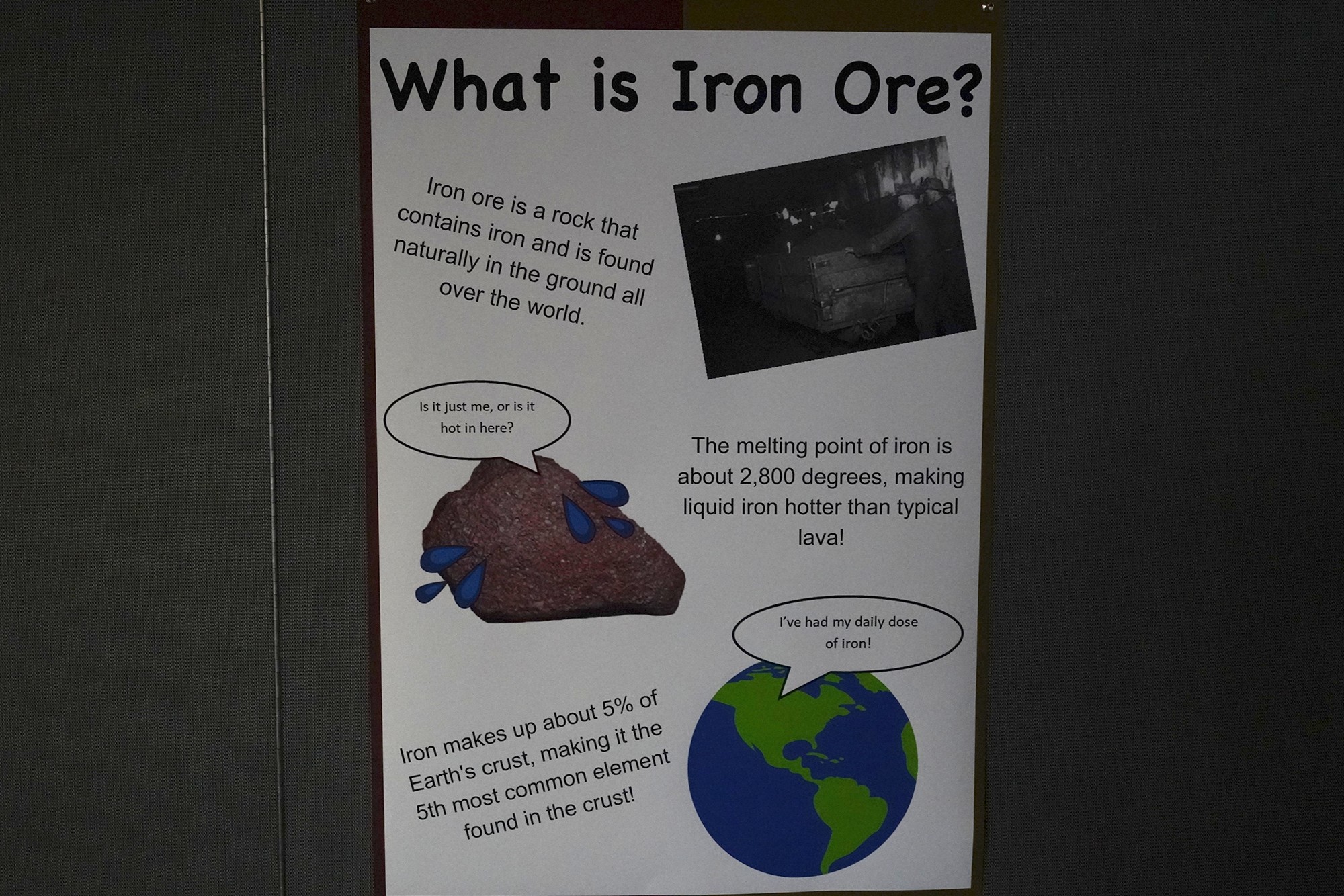

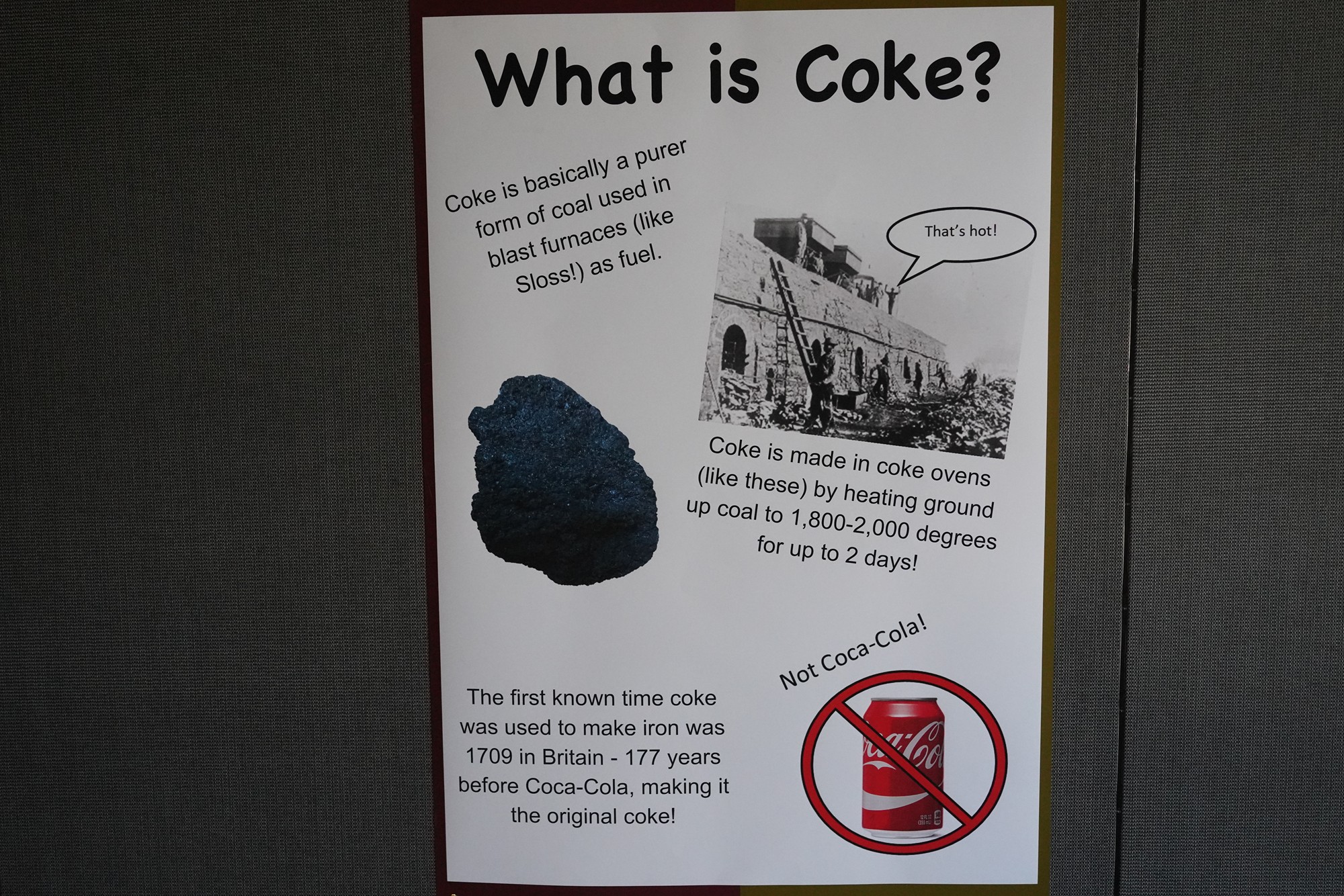

Birmingham had all the ingredients to make great iron-producing plants.

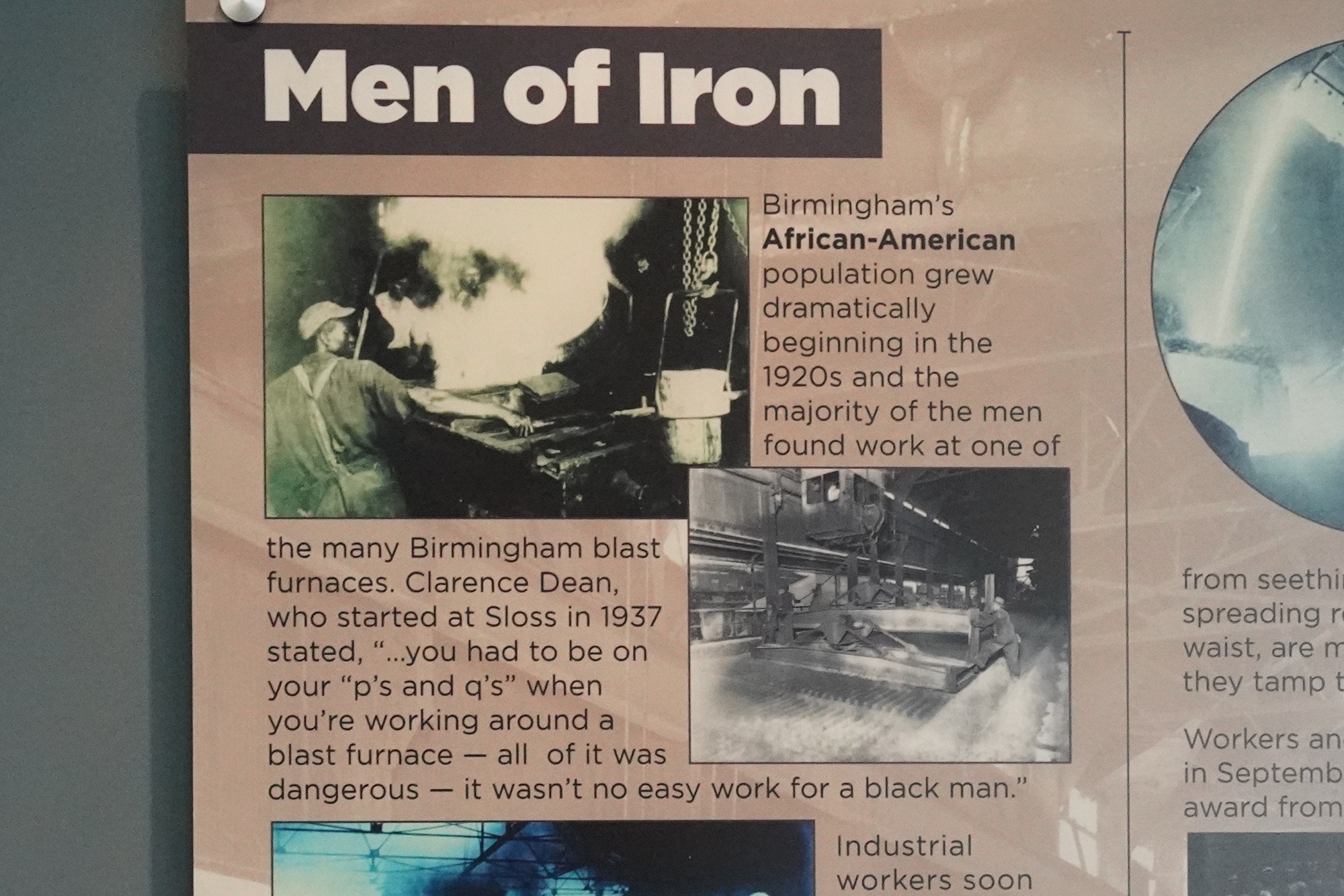

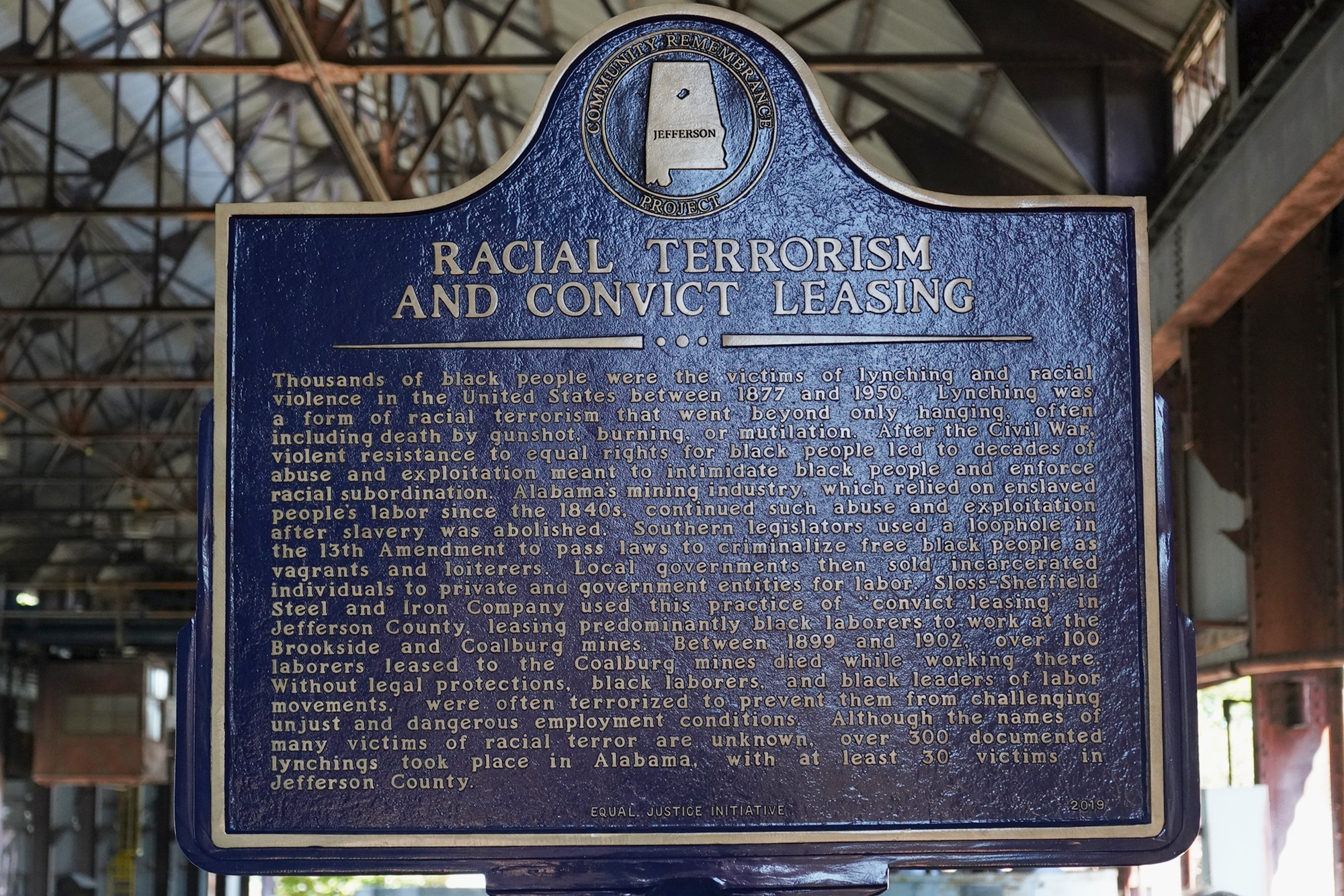

Most of the workers on the plants were blacks

They treated loitering blacks as criminals and sent them to prisons. Then the government lend them to the plants as cheap labor.

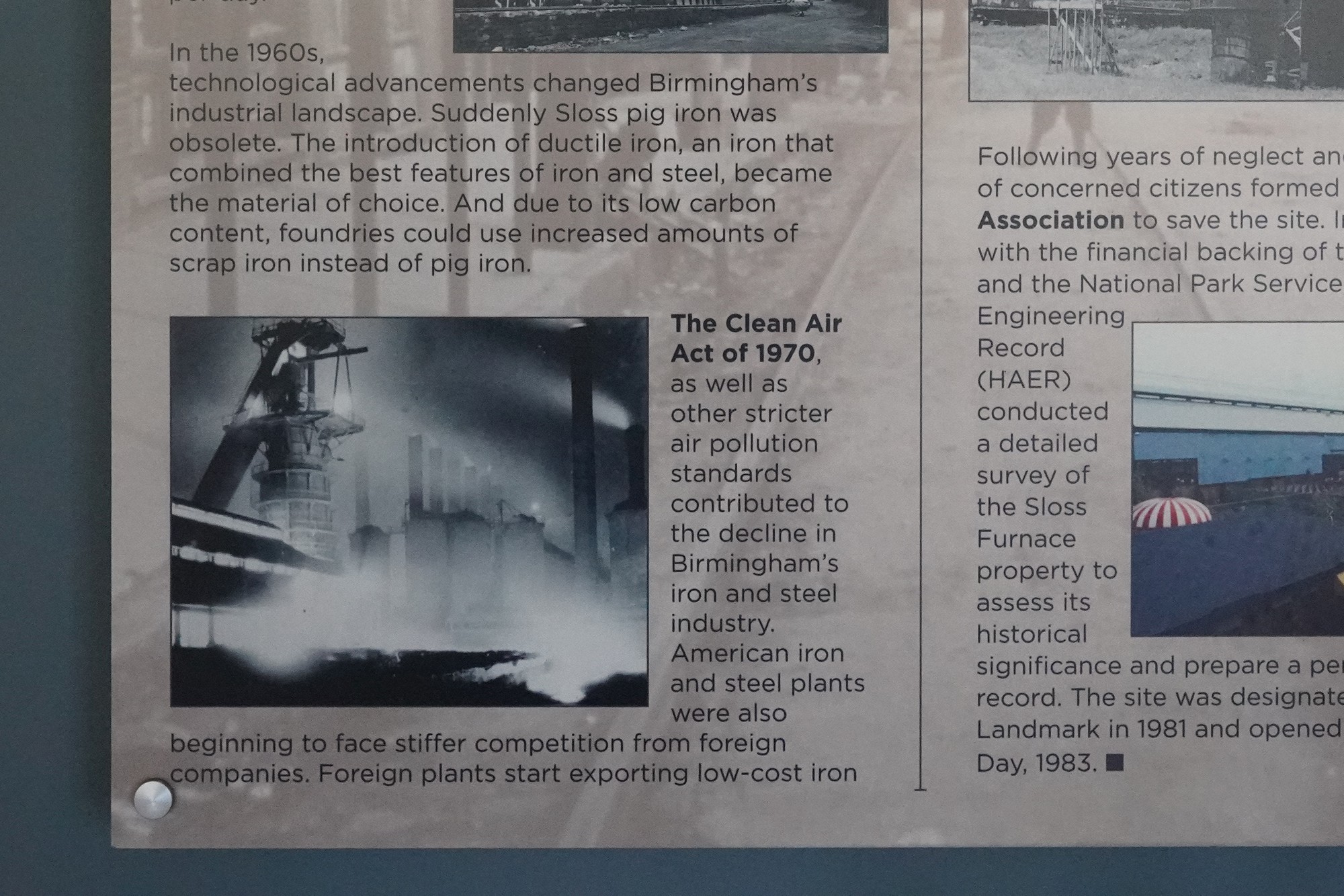

It is closed because as time passed, iron was no longer popular because of the rise of steel.

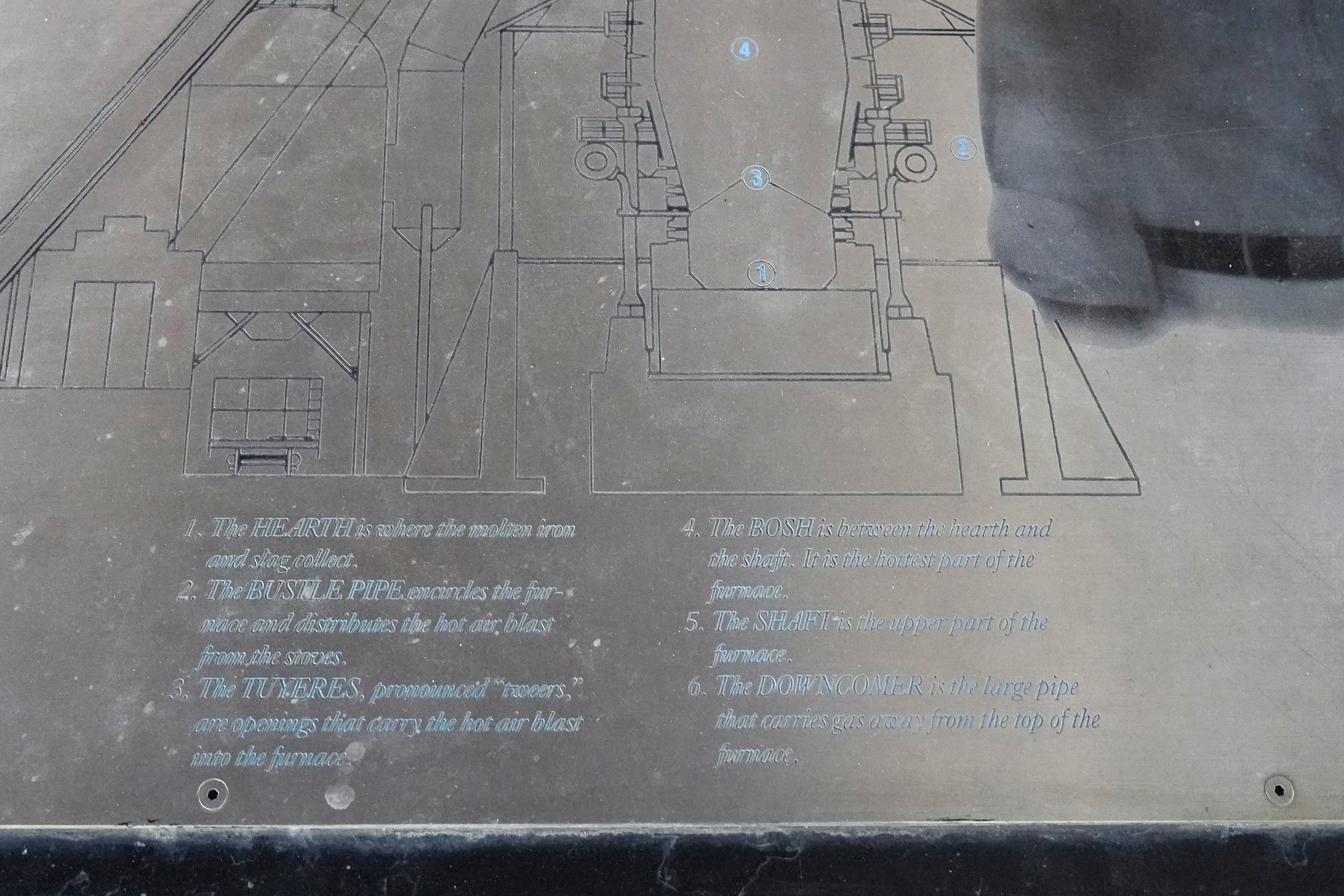

Two tall structures with inclines attached to them are the furnaces. This plant has two furnaces.

There are about ten or so boilers that run the air compressor to generate heated air needed by the furnace.

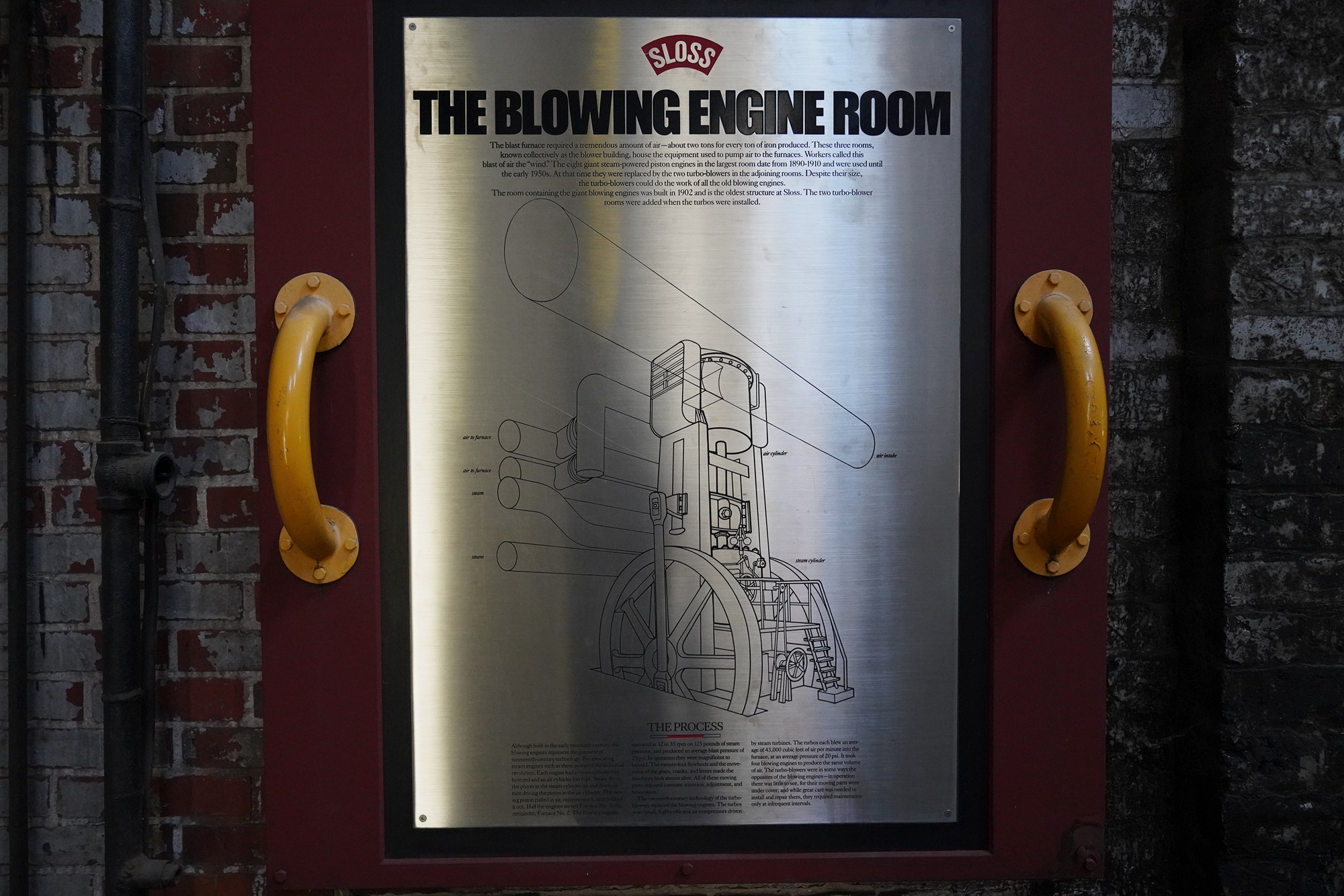

This is the air pump that pumps the compressed air into the furnace.

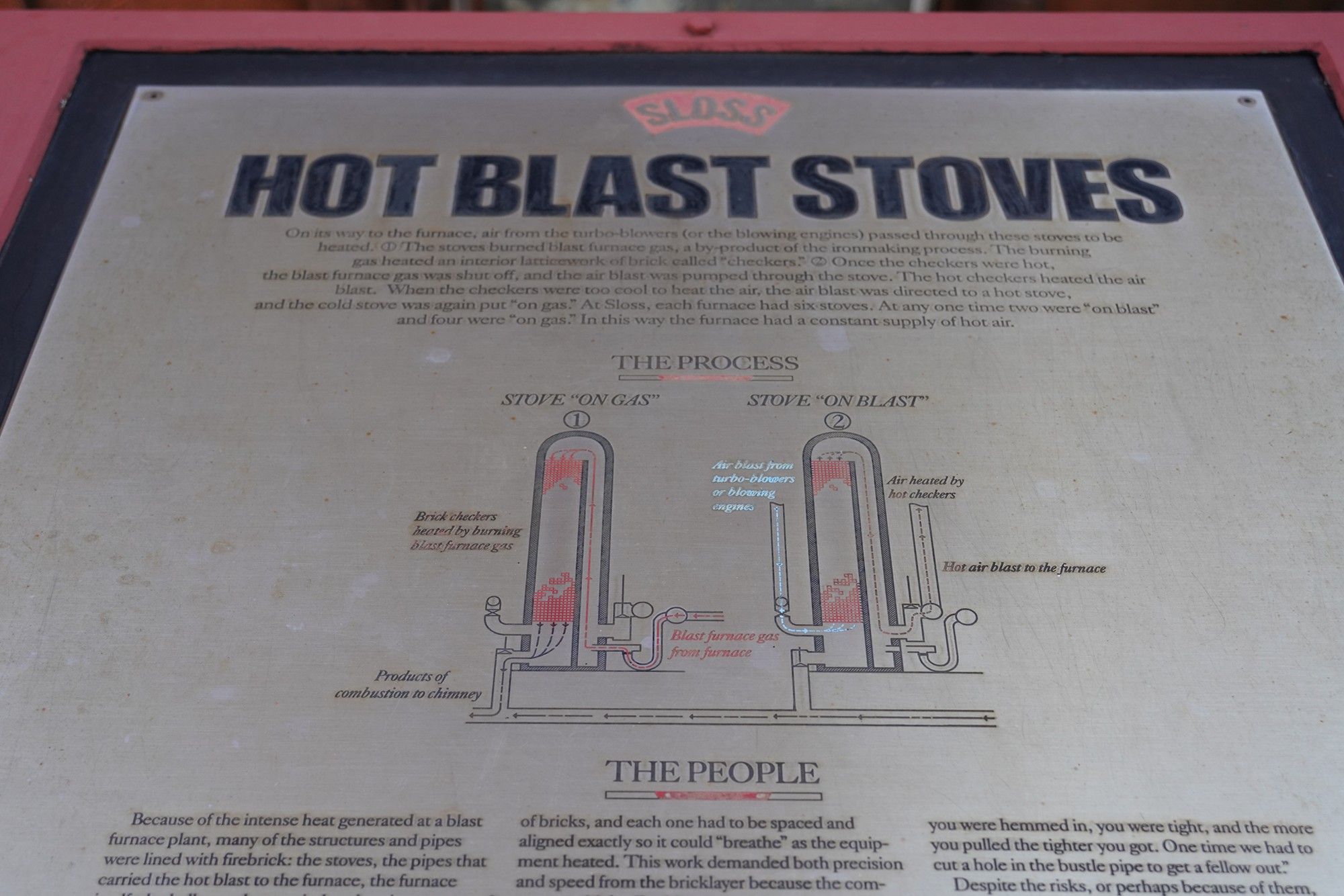

The compressed air goes into this big drum and gets heated.

The heated air goes into the furnace

The furnace

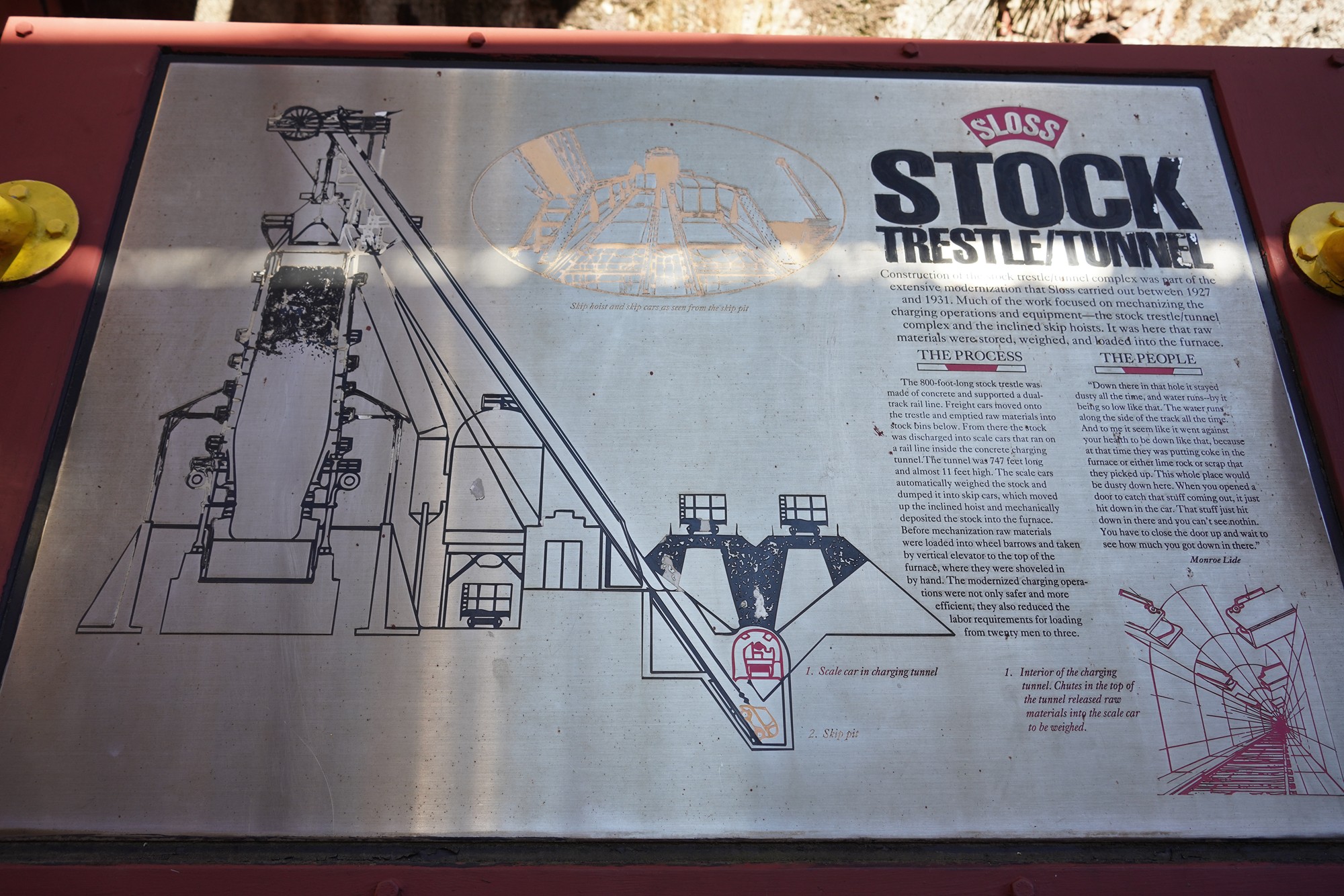

The furnace also receives the iron ore, coke, and flux from the storage to the top of the stove by the inclined hoist.

Freight cars move here and drop the mixture of ore, coke, and flux.

Then the mixture is carried by the hoist to the top of the furnace and drop it.

Then the chemical reaction with ore, coke, flux, and heated air causes the iron to separate from the ore.

The liquid iron comes out from this hole at the bottom of the furnace.

Then the liquid iron is cooled in this area to become metal iron.

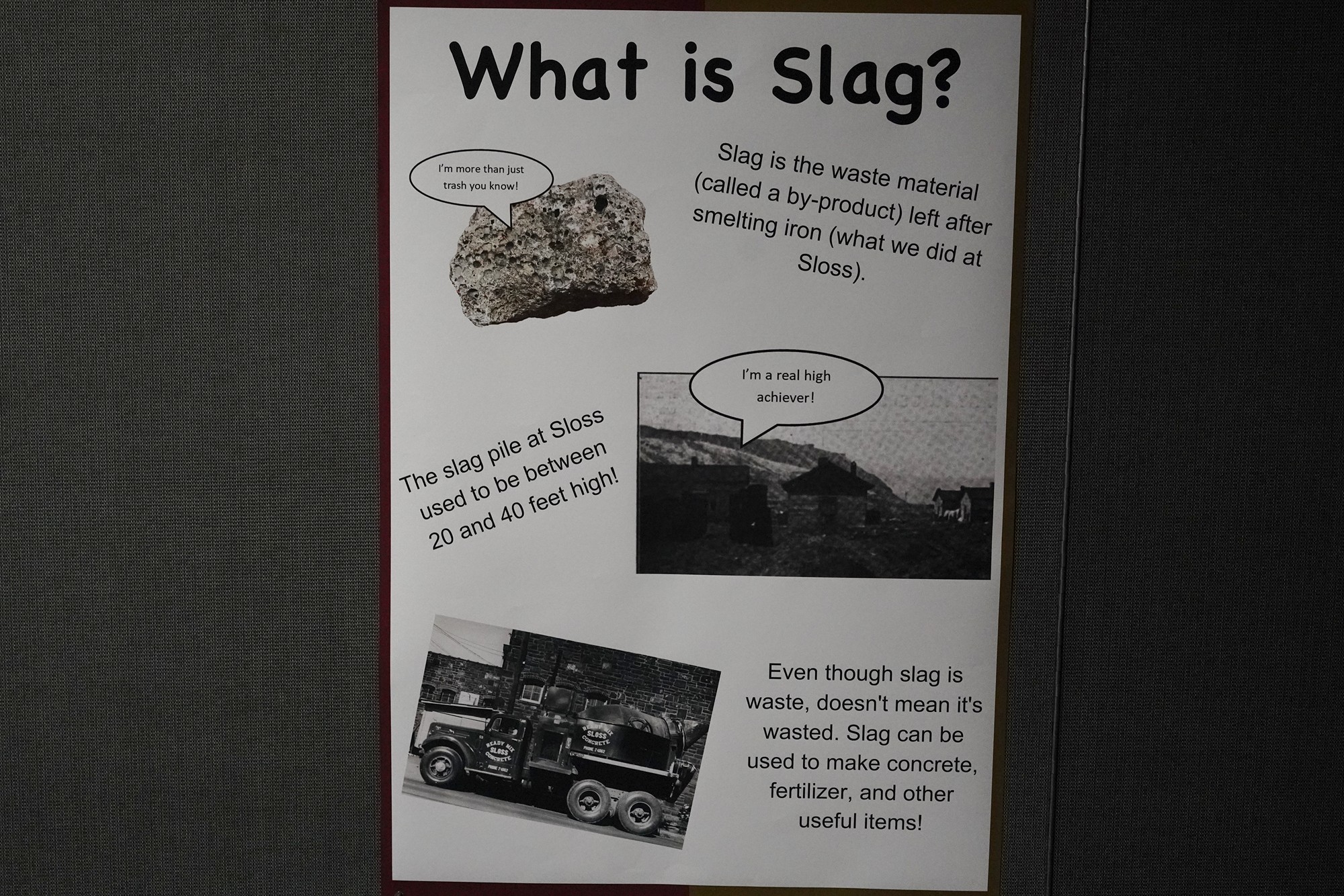

The waste (slug) comes out of this hole.

Which is processed here

Done with the plant, so going back

Metal artists use this area of the plant

Looking back